7.1 DOCUMENT CONTROL AND RECORD KEEPING SECTION

This section outlines the document control and record-keeping procedures for flight simulator maintenance in alignment with CAR 7 D VI for DGCA and EASA Part-ORA &CS-FSTD(A) issue-II.

7.1.1 CONTROL OF TECHNICAL DOCUMENTS

Technical documents, including forms, checklists, and workbooks, are integral to the day-to-day operations of the Engineering Department. Ensuring the standardization of these documents is crucial for maintaining consistent and reliable records for tracking purposes at any given time.

These documents may undergo to amendments, reforms, revisions, or re-issuance for reasons including, but not limited to, continuous improvement, standardization, optimization, or the implementation of Regulatory directives or FSB recommendations. All updates to these documents must be meticulously logged to maintain a clear history of changes.

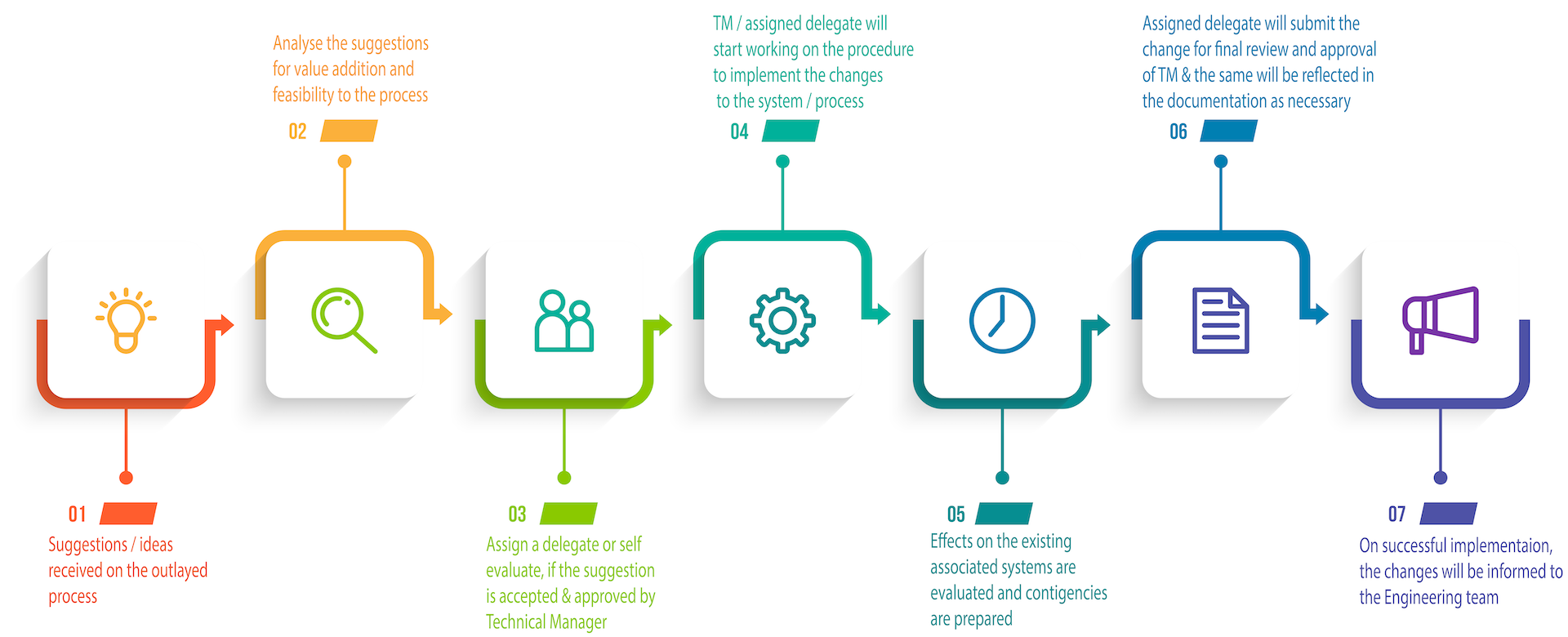

- AMENDMENT / REVISION PROCESS If a controlled document requires an amendment or revisions, it must follow the specified guidelines.

- Any ACAT employee identifying the need for an amendment or revision to a controlled document shall formally inform the Technical Manager (TM). This communication can be in via email and must include a detailed rationale for the change, highlighting its potential impact and benefits.

- TM will review the proposal and it is discreet to TM for accommodating the changes. If TM decides to amend or revise the proposal may assign the task to a delegate to work on the change, who will then revert to TM with said changes for the review.

- The TM is responsible for finalizing the changes and approving the amendment. This step includes a thorough review to ensure the changes meet the intended objectives and comply with relevant standards.

- Upon amendment approval, details must be recorded in the Document Change Log, noting the change's nature, amendment date, and involved personnel. This log acts as a concise historical record of document modifications.

- IMPLEMENTATION

- Revised documents shall be utilized post-approval of the Technical Manager. The CMM/QM may be consulted to confirm the compliance with regulations as required. Any revisions to this manual shall be notified to CMM/QM.

- The Technical Manager or the designated person releases the document, notifies all Engineering team members via email, updates the Engineering Server's Formats folder, and records the changes in the Document Control Record. This process ensures documents are legible, identifiable, and systematically maintained for easy retrieval.

7.1.2 LIST OF CONTROLLED DOCUMENTS

-

The below list of documents is maintained and controlled by the

Engineering Department and can be found in Engineering Server.

- MANUALS

- FORMS

- Snag Clearance Record Form

- Hardware Modification Form

- Software Modification Form

- Load Acceptance Form

- WORKBOOKS (FSTD SPECIFIC)

- Preventive Maintenance Workbook

- Qualification Test Guide Workbook

- CHECKLISTS

- Training Device Qualification Checklist

- Visual Database Validation Checklist

- Subjective Flight Test Checklist

- CIRCULARS

- Simulator Advisory Circular

- Simulator Engineering Circular

- LOGS

- Simulator Training Log

- Discrepancy List

- Preventive Maintenance Work Instructions

- SOFT RECORDS (CONTROLLED EXCEL)

- Discrepancy Tracker

- FSB Tracker

- Document Control Tracker

- FSTD Modification tracker

- Simulator Maintenance Procedures Manual

7.2 RECORD KEEPING

All controlled records shall be maintained in an organized and accessible record system, ensuring are traceability throughout their required retention period. It can be either in hard or soft copy, even combination of both shall be considered.

In case of hard copy long durable materials for paper records, if an electronic record system is used, the backup system may be configured to have a backup within 24 hours of new entries, with safeguards against unauthorized alterations shall be used.

Backup system should be stored separately from work data to preserve its condition and ensure redundancy. Key records and their respective retention periods are as below,

- CERTIFICATES & REPORTS (CMM/QM)

- Initial & upgrade Evaluation : Lifetime of the Device.

- Recurrent Evaluation : 5 years or at least last 3 evaluations.

- DOCUMENTS TO BE RETAINED BY ENGINEERING

- FSTD Maintenance Personnel Records (until personnel employed) Lifetime of the device

- Master QTG (MQTG) with each amendment

- A record of all FSTD modifications (affecting SOQ)

- Discrepancy & FSB Tracking System (soft records)

- FSTD Utilisation data 5 Years

- Recurrent objective & subjective test results.

- Subjective Testing Records.

- Discrepancy List and MMI along with associated data.

- Simulator Training Log (a mechanism to log comments by user)

- Calibration of FSTD Maintenance tools.

- Emergency system checks record.

- All controlled physical documentation record of maintenance and checks.

- Record keeping of QMS/CMS report, audit schedule, evaluation programme, management evaluation reports or any quality management related documents shall be referred in ACAT Quality Manual.

- In the case of electronic system all the controlled records documentation will be retained for at least 5 years.

- All the formats and records can be found in engineering repository.

7.3 ARCHIVING

- Any of these documents archived shall be intimated to all engineering team members with the specifics of archiving location and relevant data.

- Same shall be notified to quality department for their recurrent knowledge.

- Documents post retention period shall be destructed as per local regulatory policies; items will be handed over to the ACAT operations team.